Things were very different here seven years ago. In 2010, the sunspots were finally starting to return after one of the more lengthy solar minimums. Our fledgling ham radio “club” boasted a record four members and we were planning to build a big club station. That year, after a bit of an unexpected windfall, I picked up a Mosley S-33 tribander. This 3-element 17/20/40m yagi was to be one of the main antennas for the club station, along with my venerable TH6DXX but, before we could even get started, everything changed. Our club evaporated when half the members (VE8DW and VE8NE) moved away and VE8GER retired, preferring to spend most of his time out of town. I had a snazzy portable ham shack that worked fine but dragging it up to our club site to operate was also starting to get old. The time was ripe for a new plan.

In 2012 the real estate market here collapsed and I ended up moving into a house that I had been renovating for resale. It had a fairly large lot and neighbours on all sides but it also had one feature that was unusual in these parts: there were no high-voltage power lines bordering the property. All the local utilities are above ground and most everywhere there are 2400V AC lines distributing power to transformers that step it down to 120/240V for residential use. For some reason, the high tension lines stopped up the street and only the lower voltage wires were extended to feed the last three houses on the block. As a ham, this meant two things. First, the background noise would be somewhat quieter, and second, I could put up a tower or two without having to stress about proximity to high voltage wires.

|

My (somewhat) ambitious plans from 2012. The receiving antennas never worked well enough to keep them up but eventually everything else got done except the tower for the S-33. |

It took me a while but eventually, in 2013, I put up a 64-foot DMX tower for my TH6DXX yagi. It was all I could manage at the time. I knew that for the S-33 to perform on 40 meters it would need a much larger tower so it remained stacked on the ground while I tried to figure out how to do that on my meager budget. For a 40m yagi you need at least a 70 foot tower and, although I had found the space to run guy wires for my other tower (a TH6 is a bit much for an un-guyed DMX tower), I knew that the only way to fit in a second tower of that height would be with one that was free-standing. This posed several huge challenges.

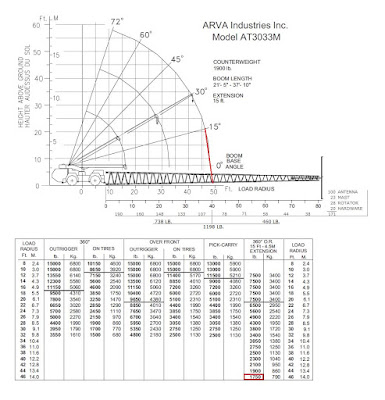

For starters, even though the S-33 is rather small for a 40m yagi, it is still a big chunk of aluminum. It weighs 100 pounds, has a 24-foot boom, and the elements are almost 50 feet each. It was going to require a substantial tower. My first inclination was a 72-foot Titan tower from Trylon. These are the ‘standard’ heavy-duty towers around here (made in Canada) but they start at about $3000 and go up from there depending on your wind loading requirements. As might be expected, they are also very heavy which means they are difficult to move, install, and ship. For a long time I also had my eye on an aluminum tower from Universal Manufacturing in Michigan. Much lighter and with a convenient tilt-over base, these looked attractive for a while when the US and Canadian dollar were at par but as the American dollar went up and up they rapidly became prohibitively expensive.

As anyone who has ever bought a tower knows, one of the other big expenses is shipping. Even knocked down and with the sections nested together, towers are bulky and heavy and shipping them all the way up here to the edge of the world costs twice as much as shipping them anywhere else in the country. No matter how hard I tried, I couldn’t find a way to get the shipping cost from the East (where all the towers come from) to the far North under $2000.

Then there is the issue of the foundation. Everything here is built on permafrost so a standard concrete foundation was out of the question. The constant freezing and thawing of the “active layer” would more than likely shift the concrete and we can’t have that. The simplest solution is to use steel pilings drilled into the permanently frozen subsoil. Once they’re frozen in below ground they usually don’t move and even if they do, it is vertical motion. There are several ways to ensure they don’t do that and almost everything up here is now built on “adfreeze piling” foundations despite their enormous cost. The price for suitable pipe can range between $800 to $3000 each, depending on the size and length. Add to that about $1000 per pipe for a drill rig to bore the hole, drop the pipe in, and backfill with a wet sand slurry to freeze it in place. Yikes! At one point I seriously considered buying a decrepit old bulldozer and just using that as a tower base…

Staring at a $10,000+ price tag to put the big Mosley in the air, suffice to say that it remained on the ground for a very long time. The XYL had no problem (more or less) with me putting up another tower but there was no way the money was going to come out of the family coffers. If I wanted to make it happen I was going to have to find a way to substantially lower the cost and I was going to have to raise the money “off the books”.

On to Part 2